Mazda 6 Service Manual: Mechanical system test

Mechanical System Test Preparation

1. Engage the parking brake and use wheel chocks at the front and rear of the wheels.

2. Inspect the engine coolant. (See ENGINE COOLANT LEVEL INSPECTION.)

3. Inspect the engine oil. (See ENGINE OIL INSPECTION.)

4. Inspect the ATF levels. (See AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION.)

5. Inspect the idle speed and ignition timing in P position. (See IDLE SPEED INSPECTION.)(See IGNITION TIMING INSPECTION.)

6. Bring up the engine and transaxle to normal operating temperature.

Line Pressure Test

1. Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

Warning

- Removing the square-head plug when the ATF is hot can be dangerous. Hot ATF can come out of the opening and badly burn you. Before removing the square-head plug, allow the ATF to cool.

2. Connect the SSTs

(49 H019 002 and, 49 0378 400C) to the line pressure inspection port, then replace the gauge of the SST

(49 0378 400C) with the SST

(49 B019 901B).

3. Start the engine, then warm up the automatic transaxle.

4. Shift the selector lever to D range.

5. Read the line pressure at idle engine speed for the D range.

6. Read the line pressure at idle engine speed for the D (HOLD), S, S (HOLD), L, L (HOLD) ranges and R positions in the same manner as in Steps 4-5.

7. Stop the engine, then replace the SST

(49 B019 901B) with the gauge of the SST

(49 0378 400C).

8. Start the engine.

9. Firmly depress the brake pedal with the left foot.

10. Shift the selector lever to D range position.

Caution

- If the accelerator pedal is pressed for longer than 5 seconds while the brake pedal is pressed, the transaxle could be damaged. Therefore, perform Steps 11 and 12 within 5 seconds each.

11. Gradually depress the accelerator pedal with the right foot.

12. When the engine speed no longer increases, quickly read the line pressure and release the accelerator pedal.

13. Shift the selector lever to N position and let the engine idle for 1 minute or more to cool the ATF.

14. Read the line pressure at the engine stall speed for the D, D (HOLD), S, S (HOLD), L, L(HOLD) ranges and R position in the same manner as in Steps 9-13.

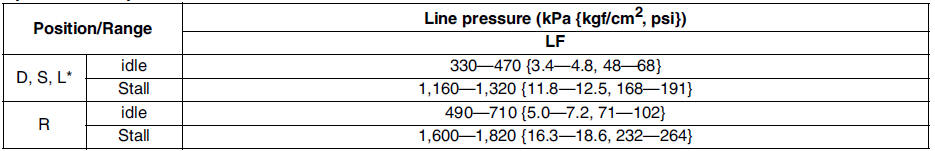

Specified line pressure

* : Includes each HOLD mode

Warning

- Removing the square-head plug when the ATF is hot can be dangerous. Hot ATF can come out of the opening and badly burn you. Before removing the square-head plug, allow the ATF to cool.

15. Remove the SSTs

.

16. Install a new square head plug in the inspection port.

Tightening torque 5.0-9.8 N·m {50-100 kgf·cm, 44-86 in·lbf}

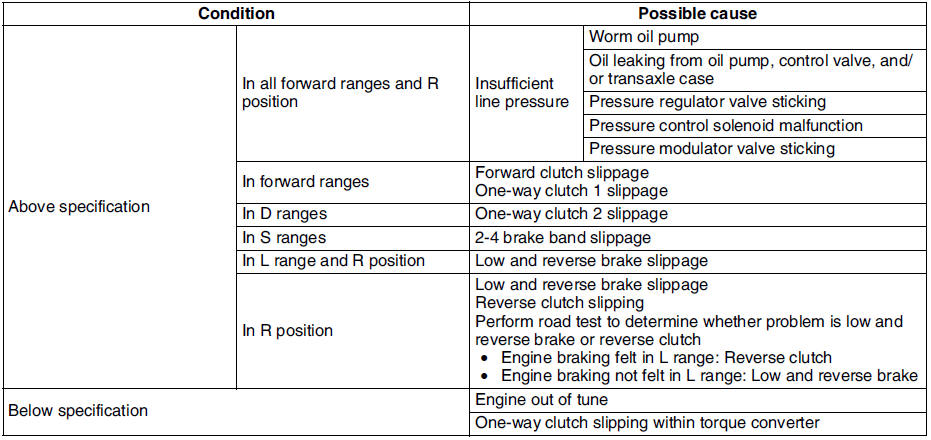

Evaluation of line pressure test

Stall Test

1. Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

2. Start the engine.

3. Firmly depress the brake pedal with the left foot.

4. Shift the selector lever to D range.

Caution

- If the accelerator pedal is pressed for longer than 5 seconds while the brake pedal is pressed, the transaxle could be damaged. Therefore, perform Steps 5 and 6 within 5 seconds of each other.

5. Gently depress the accelerator pedal with the right foot.

6. When the engine speed no longer increases, quickly read the speed and release the accelerator pedal. When the engine speed no longer increases, quickly read the speed and release the accelerator pedal.

7. Shift the selector lever to N position and let the engine idle for 1 minute or more to cool the ATF.

8. Perform a stall test of D (HOLD), S, S (HOLD), L, L (HOLD) and R range positions in the same manner as in Steps 3-7.

9. Turn the ignition switch off.

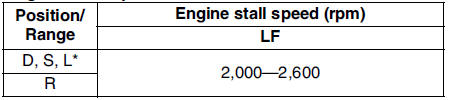

Engine stall speed

* : Includes each HOLD mode

Evaluation of stall test

Time Lag Test

1. Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

2. Use a stopwatch to measure the time it takes from shifting until shock is felt when shifting the selector lever from N position to D range (non-HOLD mode). Take three measurements for each test and take the average from the results using the following formula.

Formula:

Average time lag = (Time 1 + Time 2 + Time 3) / 3

3. Perform the test for the following shifts in the same manner Step 2.

- N position → D range (HOLD mode)

- N position → R position

Time lag

N position → D range ... 0.4-0.7 s N position → R position ... 0.4-0.7 s

Evaluation of time lag test

Road test

Road test

Warning

When performing a road test, be aware of other vehicles, people,

impediments, etc. to avoid an accident.

Note

When the legal speed limit must be exceeded, use a chassis

dynamo ...

Other materials:

Mazda 6 Service Manual: Fuel line pressure inspection

Warning

Fuel line spills and leakage are dangerous. Fuel can ignite and

cause serious injuries or death. Fuel can also irritate skin and eyes. To

prevent this, always complete the BEFORE REPAIR PROCEDURE. (See BEFORE

REPAIR PROCEDURE.)

Caution

Disconnecting/connecting the quick r ...

Mazda 6 Service Manual: Variable tumble control solenoid valve inspection

1. Remove the variable tumble control solenoid valve. (See INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION.)

2. Inspect airflow between the ports under the following conditions.

If not as specified, replace the variable tumble control solenoid valve.

If as specified, carry out the Circuit Open/Short ...